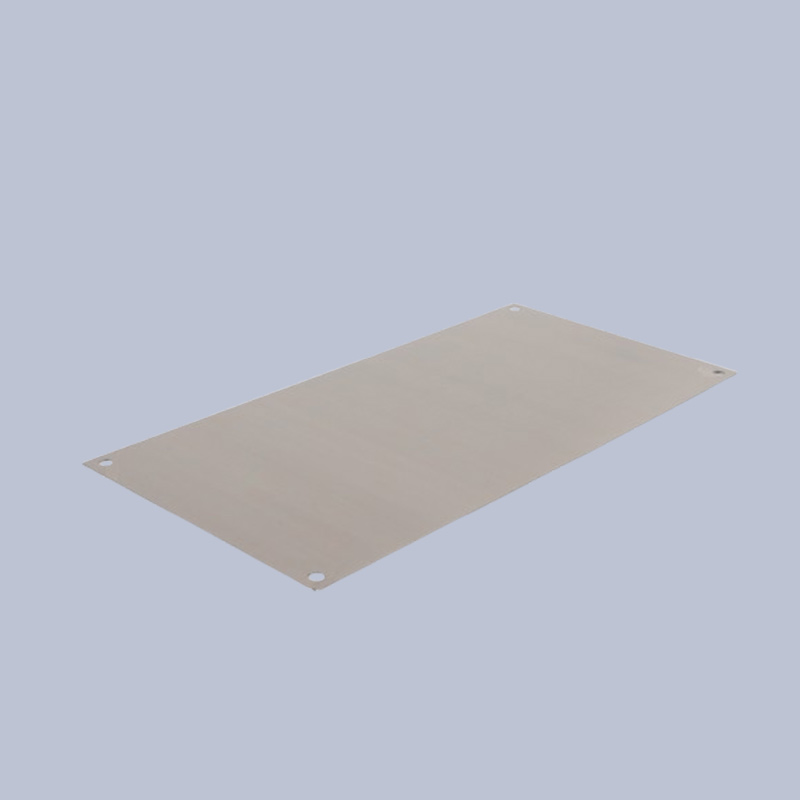

150X300X0.5 pad printing steel sheet

Product Code: Zed281101、Zed281102、Zed281103

Product Name:High quality transfer printing steel plate

Product Remarks: High quality transfer printing steel plate

Product Category: High quality transfer printing steel plate

Product Details

| DESCRIPTION: | ||||

|

|

|||

| name | Transfer printing steel plate | Transfer printing blade | ||

| Application scope | Etch the required pattern onto the steel plate | Suitable for all oil basin transfer printing machines | ||

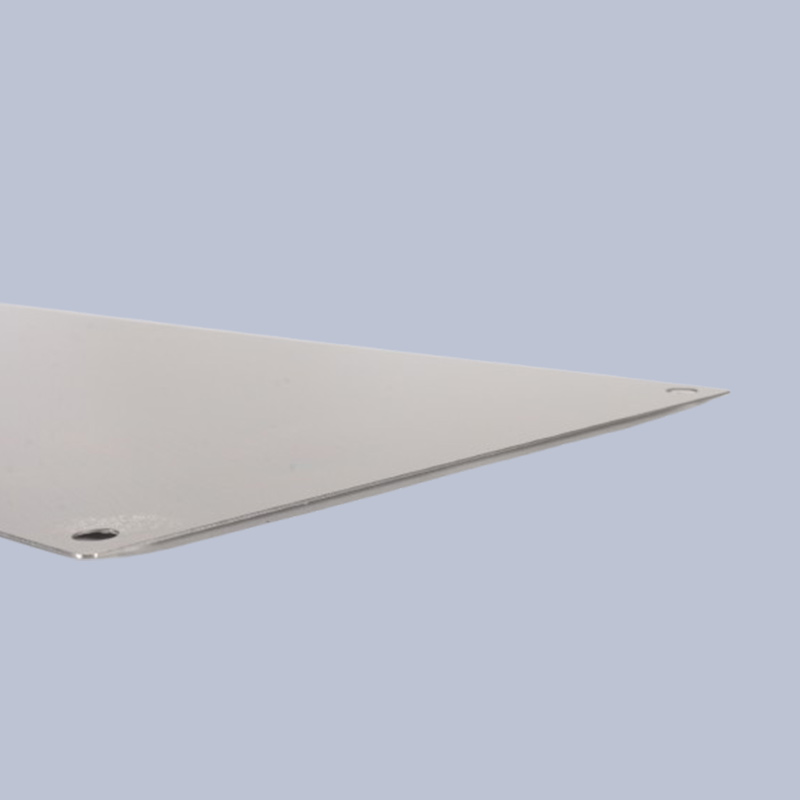

| Technical Parameter | There are steel plates made of chromium steel, K460 steel, bearing steel, spring steel, and other materials in transfer printing steel plates | Steel strip hardness: 55-60HRC (can be manufactured according to customer requirements), 2 inches, 4 inches, etc | ||

| Main specifications and models | 1、3"*4"(75*100mm) 2、3"*6"(75*150mm) 3、4"*4"(100*100mm) 4、4"*6"(100*150mm) 5、4"*8"(100*200mm) 6、6"*6"(150*150mm) 7、6'*8'(150*200mm) 8、6"*10"(150*250mm) 9、6"*12"(150*300mm) 10、4"*30"(100*750mm) 11、10"*32"(250*800mm) ...... |

1. The material is made of high-quality alloy tool steel imported from Japan, with clean ink scraping and good flexibility; 2. The blade is straight without burrs, sharp and durable; 3. Common specifications: 350 * 18 * 0.5mm Other specifications are as follows: Thickness: 0.5mm Width: 18mm/20mm Length: 350mm/400mm/500mm/550mm Among them, the cutting blade has 4 folding sections and 18 folding sections. |

||

| Functional Features | 1. Steel plate cleaning (washing), removing oil and dust from the steel plate, must be done correctly, without stains or dust; 2. Apply photosensitive adhesive evenly on the surface of the steel plate and let it dry for later use; 3. Stick the film on the appropriate position of the steel plate and fix it with transparent tape; 4. Plate drying, the glass of the plate drying machine is clean and dust-free, and the photosensitive adhesive surface is tightly attached to the plate drying machine glass; 5. Developing can be done by rinsing with developer solution for 20-40 seconds, followed by rinsing with clean water. 6. After drying the water, use adhesive tape to stick it to the areas that do not need to be etched, and then fill the sand holes. 7. Corrosion, pour in corrosive solution for corrosion. 8. Wash off the photosensitive adhesive with plate washing water and complete the plate making process. |

|||